Steel Mill Solutions

Reduce Mill Downtime, Reduce Cost

Atlas has dedicated years to the research and development of new processes for quickly and cost-effectively refurbishing pot rolls and equipment, and methods of manufacturing bridle rolls and furnace rolls to outlast everything on the market. Everything we offer translates to longer campaign life, less downtime, and reduced rebuild expense.

Send our engineering team an inquiry or give us a call at 1-855-GO-ATLAS to quickly tap into our knowledge and recommended solutions for your mill.

Sink and Stab Roll Manufacturing and Refurbishment

Atlas can design and manufacture new rolls to custom specifications, or we can build to drawings you provide. Our complete roll refurbishment service is second-to-none, with stripping, machining, and coating under one crane hook. Ask about our advanced coatings, bearing solutions, and our pot-rolls-as-a-service offering.

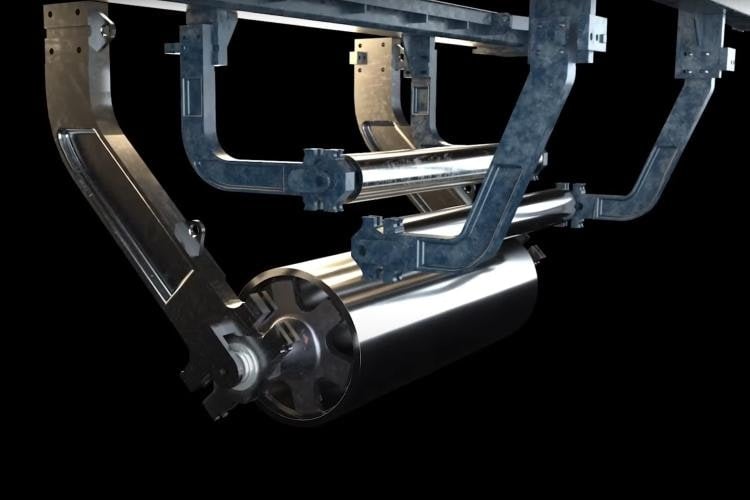

Pot Equipment Manufacturing and Refurbishment

Atlas can design and manufacture new pot components to custom specifications, or we can build to drawings you provide. We also offer turnkey refurbishment of nearly all components, including arms, bearings, bearing chocks, and sleeves. Ask about our advanced materials and cladding, as well as our pot-equipment-as-a-service offering.

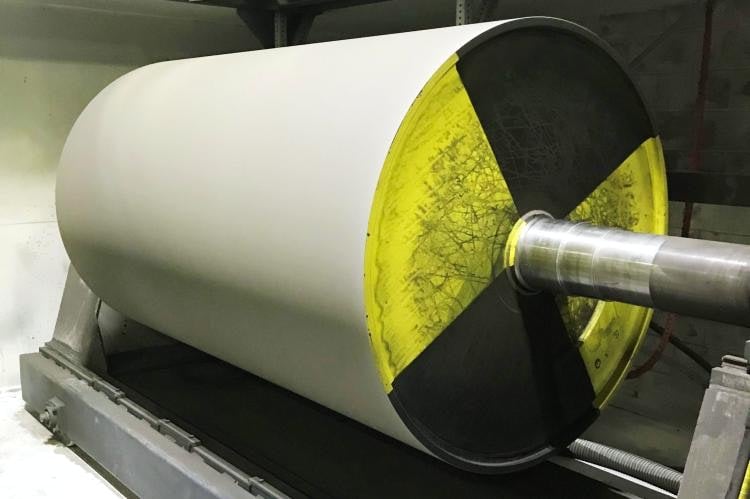

Process Roll Manufacturing and Refurbishment

Atlas can design and manufacture new process rolls of all types (bridle, deflector, tower, backup, internally cooled rolls and more - up to 80" in diameter) to custom specifications, or we can build to drawings you provide. In addition, we can recommend weld overlay, cladding, and thermal spray coating options to improve performance and increase useful life.

Furnace Roll Manufacturing and Refurbishment

Atlas can design and manufacture new rolls to custom specifications, or we can build to drawings you provide. We have developed close relationships with suppliers that provide the highest quality centrifugally and statically cast specialty materials, and we've spent countless hours perfecting our welding process to achieve uniform thermal expansion rates to prevent premature roll failure. Ask about our furnace roll manufacturing, refurbishing, and recycling offerings.

Bearings and Bushings

Altas supplies long-lasting products that provide optimal results over the life of the campaign. In addition to pot roll refurbishment, we stock, supply, and install bushings and sleeves.

Available Bushing Materials:- Stellite

- Laser cladding

- Ceramics

- T-800

Ceramic Journals

This technology works in all pot chemistries including:

- Galvanize (GI/GA)

- Galvalume (AZ)

- Aluminize (AL/AlSi)

Interested in learning more?

Submit an inquiry to our steel mill solutions team, or give us a call at 1-855-GO-ATLAS.

Atlas Revolutionizes Galvanizing Pot Maintenance with Innovative Ceramic Coating and Robotic Application

Atlas Revolutionizes Galvanizing Pot Maintenance with Innovative Ceramic Coating and Robotic Application Atlas's breakthrough technology is..

Breakdown at Steel Mill Requires Quick Response

A sudden major breakdown at a U.S. steel mill reduced its production by 50%--potentially costing the mill hundreds of thousands of dollars in lost..