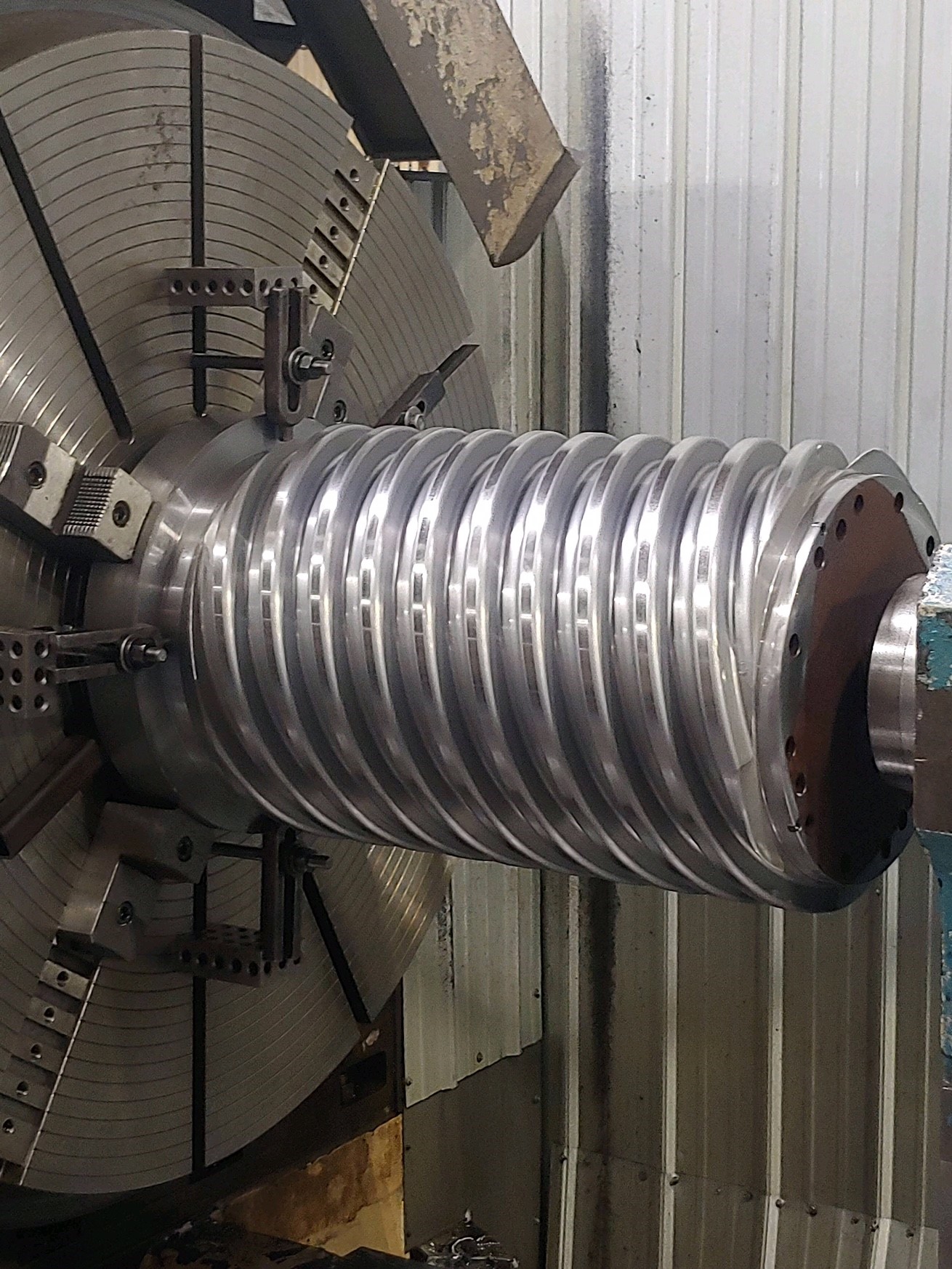

Large Turning Capabilities

Do you have extra-large parts that need to be turned/machined?

Explore Atlas' Capabilities

When the time arises to get a large part made or repaired, you can count on Atlas Machine to have some of the largest turning capabilities in the Midwest. It doesn’t matter if you have a large five-lead thread bronze nut for a 3600-ton screw press, a massive expanding mandrel, or a huge cement plant roller; Atlas Machine can handle your needs. We have the capacity to handle both large diameters and long length components with our extensive array of manual horizontal/vertical lathes and CNC horizontal/vertical lathes.

Do you have a large part that needs made new or repaired by welding/thermal spray, then turned back to OEM specifications?

Well, you have come to the right place, because we can do all of these here at Atlas Machine.

What large parts do you use in your manufacturing facility?

- Furnace Rolls

- Calender Rolls

- Table Rolls

- Pulverizer Shafts

- Pump Shafts

- Mixer Shafts

- Shredder Shafts

- Fan/Blower Shafts

- Expanding Mandrels

- Stub Mandrels

- Flanges

- Spacers

- Bearing Lock Nuts

Large Part Turning Capabilities Overview:

Manual Horizontal Lathes

12” diameter (12” over the carriage) x 54” between centers

19” diameter (13.75” over the carriage) x 72” between centers

22” diameter (16” over the carriage) x 120” between centers

24” diameter (25.5” over the carriage) x 236” between centers

47” diameter (35” over the carriage) x 360” between centers

60” diameter (54” over the carriage) x 260” between centers

Manual Vertical Lathe

42” diameter x 35” height

CNC Vertical Lathe

96” diameter x 59” height

CNC Horizontal Lathes

12” diameter (12” over the carriage) x 40” between centers

12.5” diameter (20” over the carriage) x 60” between centers

24.4” diameter (16.54” over the saddle) x 25.59” between centers

32” diameter (25.5” over the carriage) x 144” between centers

34” diameter (28.5” over the carriage) x 144” between centers

37.4” diameter (25.6” over the saddle) x 118.1” between centers

39” diameter (32” over the saddle) x 122” between centers

39.37” diameter (38” over the saddle) x 159” between centers

78.74” diameter (66.92” over the carriage) x 275.59” between centers (Turn/Mill Capability)

Explore Atlas' Capabilities

If your large part needs to be turned on our manual lathes, you can rest assured that our highly skilled machinists have the right tools to get the job done. If we utilize one of our CNC lathes, we use the latest CNC programming/CAD software to ensure that even the most challenging geometry features can be turned/machined into various materials such as aluminum, carbon steel, brass, stainless steel, etc. Overall, we’ll ensure that your large part is turned/machined to your specified tolerances as fast and as efficiently as possible.

Contact us today to discuss your large part-turning needs.