TS Series Industrial Compressors

Featuring the *New* Sullair TS 190-260, TS-32S, and V-320TS Series Two-Stage Rotary Screw Air Compressors

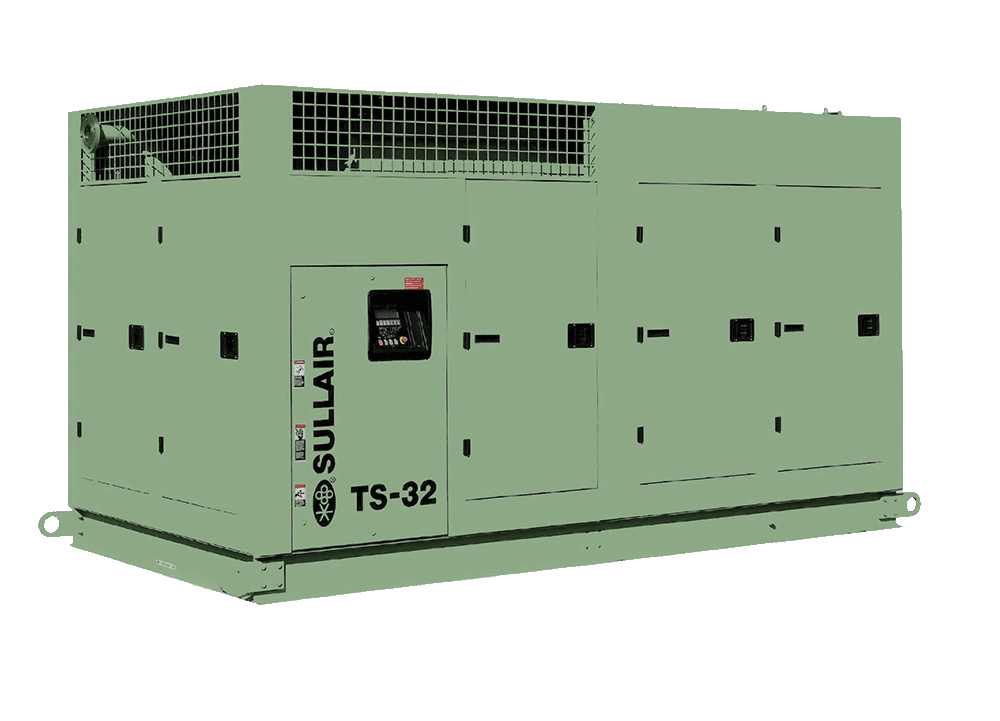

*New* Sullair TS 190-260 Series Two-Stage Rotary Screw Air Compressor

THE MOST EFFICIENT SULLAIR EVER

Anticipate significant energy efficiency gains with the New Sullair TS 190-260 Series Two-Stage Rotary Screw Air Compressors. The engineers at Sullair meticulously focused on enhancing efficiency, and their efforts have yielded remarkable results. Please call 1-855-GO-ATLAS (462-8527) for more information on the New Sullair TS 190-260 Series.

Constructed upon the foundation established by the groundbreaking Sullair LS Series Single Stage Rotary Screw Air Compressors, which revolutionized the industry and garnered substantial demand since 2017, the New Sullair TS 190-260 Series extends the established performance and innovative design of the Sullair LS package into two-stage compression.

- Best-in-Class Efficiency*

- Ease of Use & Ease of Service

- Legendary Sullair Durability

- 10-Year Sullair Air End Warranty

- 5-Year Warranty Covers: main motor, fan motors, aftercooler oil cooler, separator vessel, and variable speed drive (if equipped)

* Based on current (March 2024) efficiency data published in accordance with the Compressed Air and Gas Institute (CAGI) third-party verification program.

250 – 350 HP, 984 – 2033 cfm, 100 – 200 psi

.jpg)

Features and Benefits

- Two-Stage Air End

The most efficient Sullair Two-Stage Air End EVER- Innovative over/under design with integrated gearbox

- Patent-pending interstage cooling for increased efficiency and low pressure drop

- Optimized gearing for maximum efficiency

- Sullair OptimalAir® Air Filter

- High-efficiency/heavy-duty inlet filter holds up to five times more contaminant than conventional cellulose filters

- Cleaner intake air keeps fluid clean and extends component life

- 99.9% efficiency per ISO 5011

- Sullair Air-Fluid Separator

- Designed for low pressure drop, reducing energy requirements - ASME and CRN approved

- Cooling System

- Heavy-duty, oversized cooling system designed for 46°C (115°F) applications

- Motor

- Super Premium Efficiency (IE4) TEFC motors

- Standard on Fixed Speed and Electronic Spiral Valve models

- Premium Efficiency (IE3) TEFC motors

- Standard on VSD models

- Heavy-duty, slow running 1800 rpm design

- Extended life when compared to higher RPM motors

- 104°F (40°C) ambient motor temperature rating

- Class F insulation, Class B rise for higher temperature operation

- Genuine Sullube® Factory Fill

- Enhanced Sullair Touch Screen (STS) Controller

- 10˝ color screen for easy viewing and intuitive operation

- Integrated graphing and trending to analyze compressor performance

- Sequencing up to 16 compressors

- AirLinx® Remote Monitoring

- Connect anywhere to keep an eye on compressor operation, and reduce the risk of unplanned downtime

- Monitor pressure, temperature, running hours and service hours

- Alerts for service and warnings

- Data stored at 15-minute intervals

- Customizable reporting, from Basic to Advanced

- Real-time information through cellular connection

- Wye-Delta starter

- Zero loss drain

- Phase monitor

- Enclosure with hinged panels

- Easily removable for service

- Standard full base frame

- Helps keep dust and debris out of the unit

- Zero loss drain

- Phase monitor

- Enclosure with hinged panels

- Easily removable for service

- Standard full base frame

- Helps keep dust and debris out of the unit

- 10-Year Diamond Warranty*

- *Maintaining the Sullair 10-Year Diamond Warranty requires using Genuine Sullair parts, Sullube®, and participation in the oil sampling program. Restrictions apply.

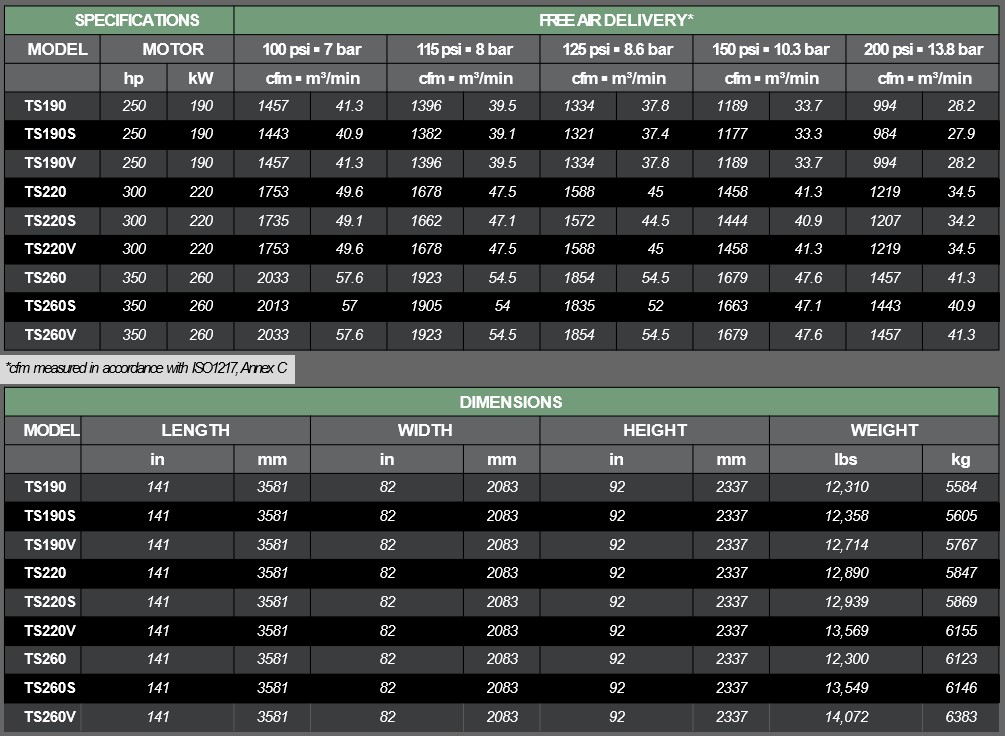

Models and Specs

Flow

984 - 2033 cfm

27.9 - 57.6 m³/min

Pressure

100 - 200 psi

7 - 13.8 bar

Power

250 - 350 hp

190 - 260 kW

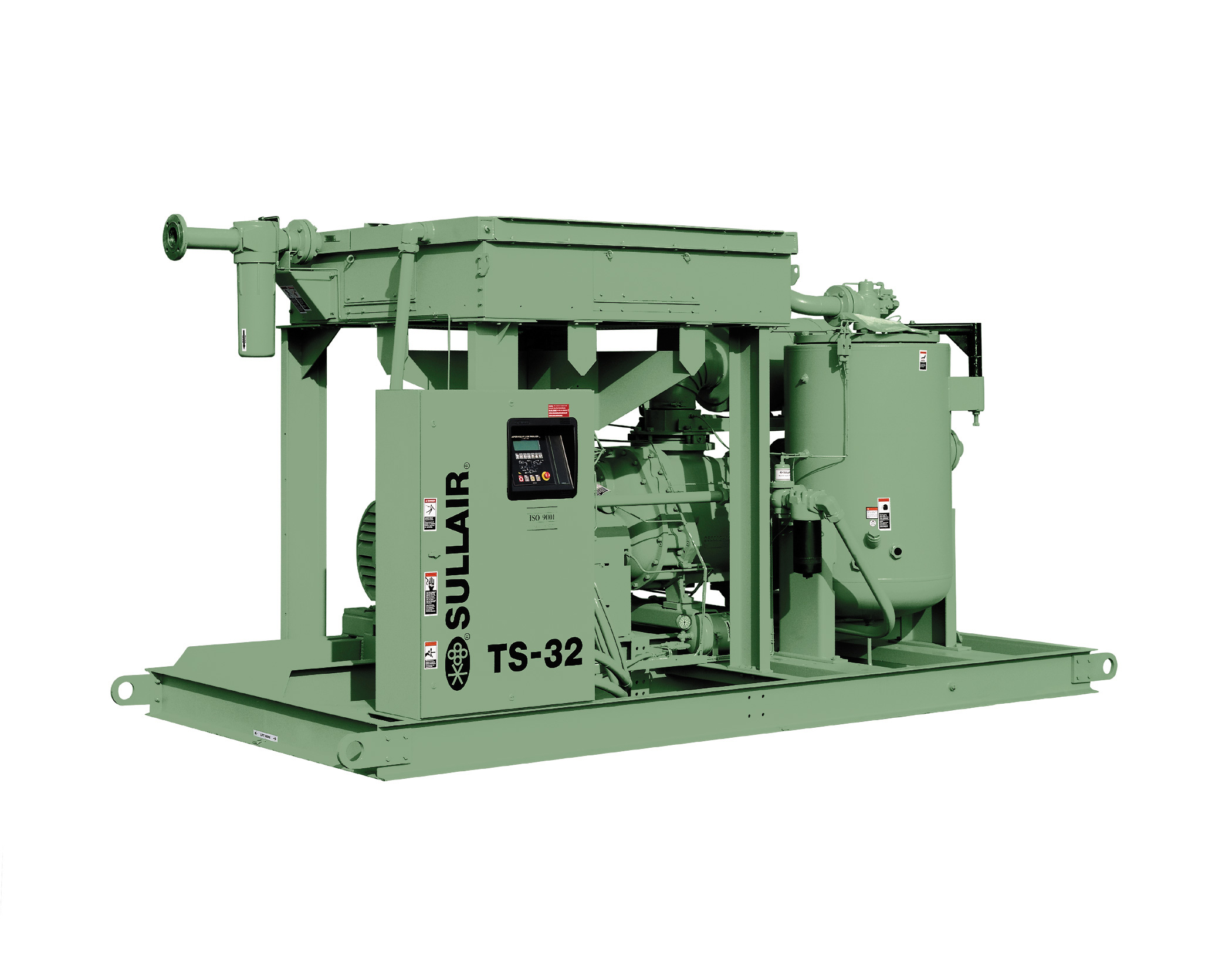

Sullair TS-32S and V-320TS Two-Stage Rotary Screw Air Compressors

TWO-STAGE SERIES COMPRESSORS

Sullair's two-stage tandem compressors feature a unique end-to-end rotor arrangement, ensuring superior efficiency both at full-load and part-load conditions. With a remarkable two-year payback period on energy savings compared to single-stage compressors, these units are tailored to match system requirements, minimizing cycle time and extending operational lifespan. Delivering a 13% boost in efficiency over single-stage screw compressors during full-load operation and a remarkable 30% improvement at part-load, they stand as a pinnacle of compressor technology. Please call 1-855-GO-ATLAS (462-8527) for more information on the Sullair TS-32S and V-320TS Series.

- Two-stage Technology, High-Performance, Energy-Efficient Design, Superior Longevity Air End Life

- Supervisor Microprocessor Controller

- Legendary Sullair Air End – Decades of Proven Performance and Efficiency

- Two-Stage Standard and Extreme Pressure Models Available

- 10-Year Air End Warranty

- 5-Year Warranty covering the motor, coolers, and air/fluid vessel

200 – 600 HP, 945 – 3000 cfm, 100 – 150 psi

Features and Benefits

Two-Stage Standard Pressure Models- Multi-Stage Air-Fluid Separation

- Dual nested Optimizer™ separator elements, reduce fluid carryover to a maximum of 1 ppm

- Pleated Optimizer elements lower initial pressure drop for greater efficiency and extends element life

- Fiberglass Fluid Filter

- Aircraft-quality media provides better filtration

- Up to 20% more efficient than conventional paper elements

- Optimalair® Heavy-Duty Air Intake Filter

- Provides finest inlet filtration in the industry (99.95%+ overall efficiency/0.4 micron)

- Reduces pressure drop throughout the operating life, resulting in energy savings

- Two-Stage Compressor Air End

- Delivers more air

- Reduces power consumption

- Enhanced Serviceability for Air-Cooled Oil Cooler and Aftercoolers

- Easy to remove panels provide access for cleaning coolers

- Motor Coupled to Air End Through Non-Lubricated, Flexible Coupling

- Allows use of standard NEMA frame motor

- Simplifies installation and start-up

- Variable Capacity Control System Featuring Spiral Valve Technology

- Lowers part-load operating costs

- Maintains consistent plant pressure

- Sullair Supervisor™ Controller

- Computer-compatible microprocessor controller has simple graphic illustration of monitored functions and an easy-to-read keypad

- On-demand readout of all operating and maintenance conditions

- Easy Maintenance

- Time Proven End-to-End Design

- NEMA 4

- Wye-Delta starter for softer start

- Bearing Fluid Reservoirs

- Extend air end life

- Genuine Sullube® Factory Fill

- A 10,000-hour extended-life synthetic fluid powered by Dow technology, Sullube has been used in more than 50,000 compressors worldwide

- Sullair 10-Year Diamond Warranty*

- *Maintaining the Sullair 10-Year Diamond Warranty requires using Genuine Sullair parts and Sullube, as well as the oil sampling program.

*Options for Two-Stage Standard Pressure Models:

- PristineFG™

- Food Grade designed specifically for compressors used in food, beverage and pharmaceutical applications and meets FDA and USDA H-1 requirements

- Variable Speed Drive (VSD)

Two-Stage Extreme Pressure Models

- Dependable, high-performance two-stage air end for maximum power savings

- 460v motor coupled to air end via non-lubricated, flexible coupling

- Allows use of Standard NEMA frame motor

- Flange-mounted for positive alignment

- Sullair Supervisor Controller

- Easy pressure adjustment

- Capacity modulation range 100 to 40%

- Heavy-duty inlet air filter

- Two-stage, dry type

- Air-fluid separation

- ASME psi rated tank

- Pleated air-fluid separator element for lower initial pressure drop

- Cooling

- Air-cooled units use mounted and piped aftercooler with quiet fan

- Water-cooled units feature an air-in-shell, water-in-tube aftercooler design

*Options for Two-Stage Extreme Pressure Models:

- Magnetic starter

- Solid state starter

- Sound attenuating enclosure with removable panels

- 575v

Models and Specs

Two-Stage Standard Pressure Models

60 Hz

- TS-32S—400 to 600 hp (298 to 447 kW), 1681 to 3000 cfm (47.6 to 84.9 m3/min), 100 to 150 psi (6.8 to 10.3 bar)

- V-320TS—200 to 450 hp (149 to 336 kW) Variable Speed Drive (VSD), 945 to 2310 cfm (26.7 to 65.4 m3/min), 100 to 150 psi (6.8 to 10.3 bar)

Two-Stage Extreme Pressure Models

- Please call 1-855-GO-ATLAS (462-8527) for information on the Sullair Two-Stage Extreme Pressure Models.

Flow

945 – 3000 cfm

26.7 - 84.9 m³/min

Pressure

100 – 150 psi

6.8 - 10.3 bar

Power

200 – 600 hp

149 - 447 kW